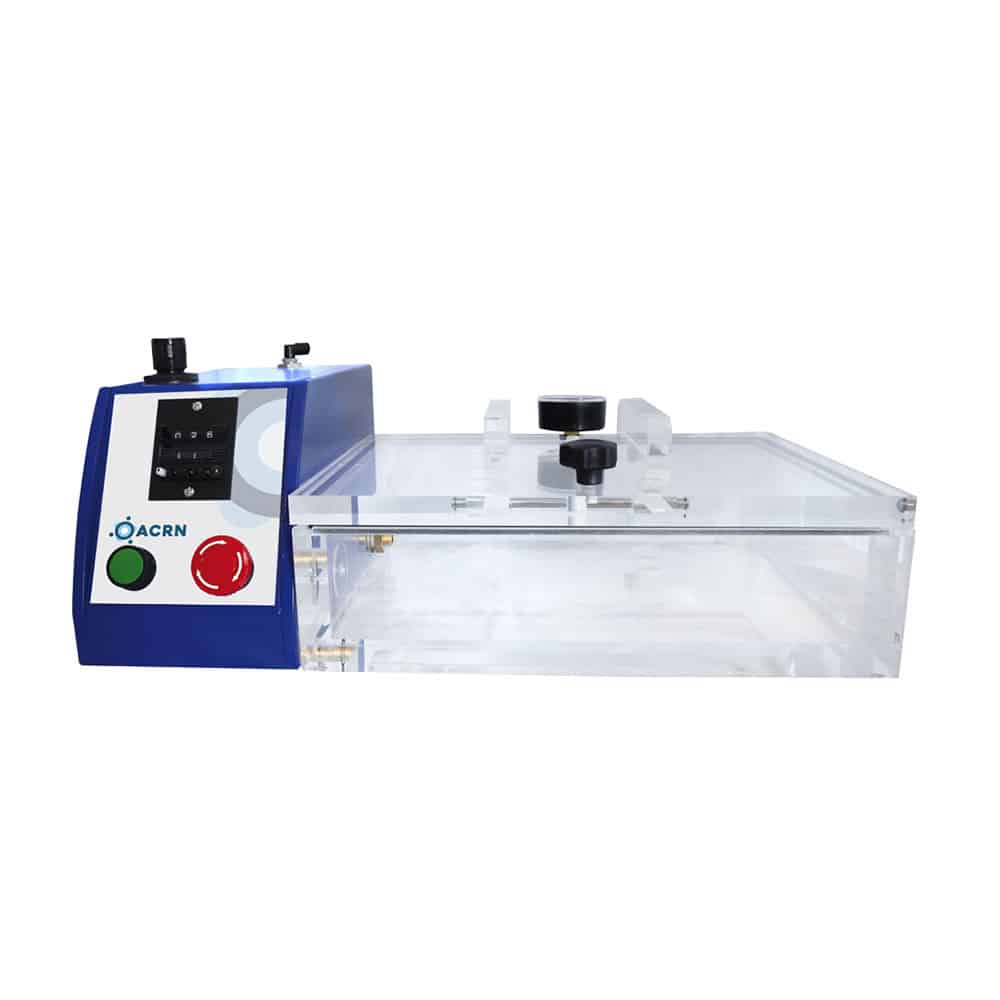

Packaging Leak Tester CTE

Robust model and versatile

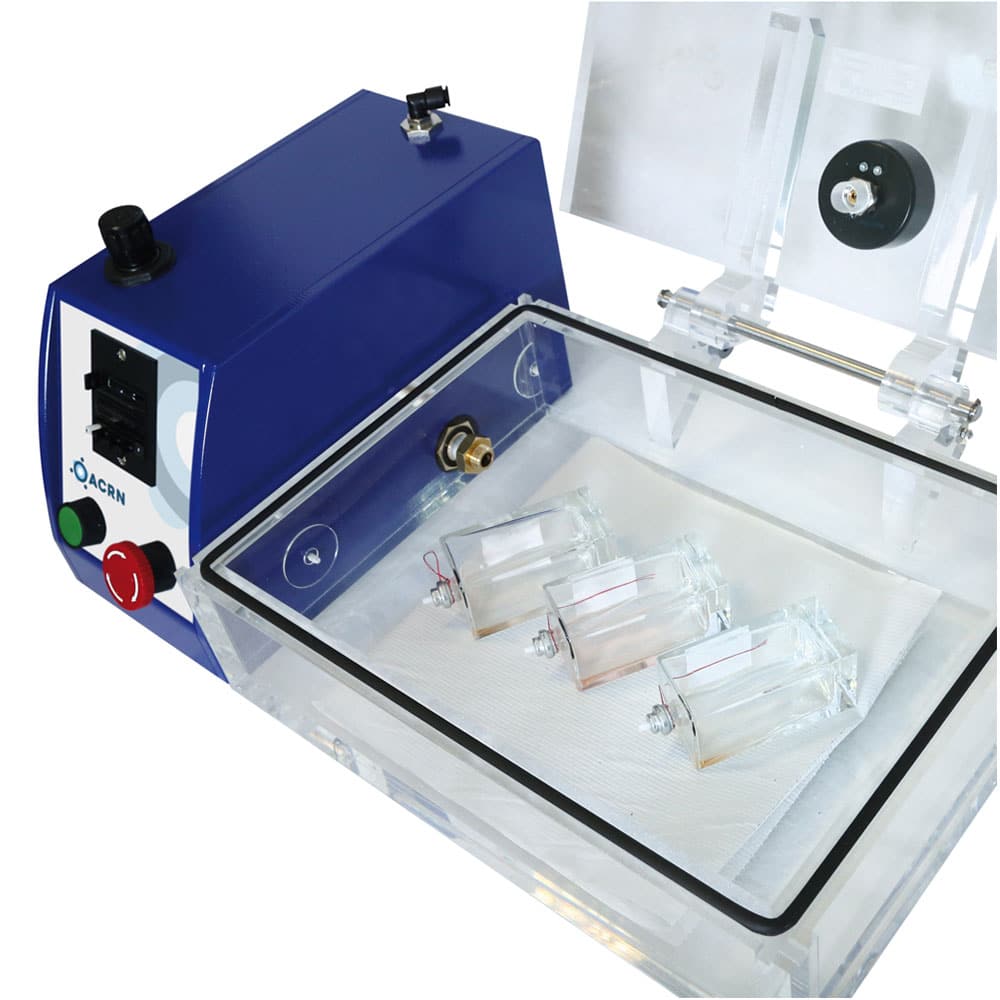

It is used to test the tightness of packaging containing liquid or semi-viscous products, by depression, directly on the production line with a total visibility, thanks to its plexiglas design.

Just lay down your sample to immerse your cap. The use of blotting paper by example, allows you to see if the product has leaked from the sample during the test.

Description

Profits

The CTE is a practical and cost-effective packaging leak tester designed for daily use in industrial environments.

With its vacuum regulator and built-in timer, it enables consistent and repeatable tests to ensure packaging integrity at every stage — from incoming raw materials to final product inspection. Its simplicity and robustness make it an ideal tool for quality control teams looking for efficiency without compromising reliability.

- Fast, ergonomic and easy to use

- Reliable and economical

- Adapted to the production envrionment / Robust

- Test on receipt of raw materials, in production, before shipment

- Low maintenance

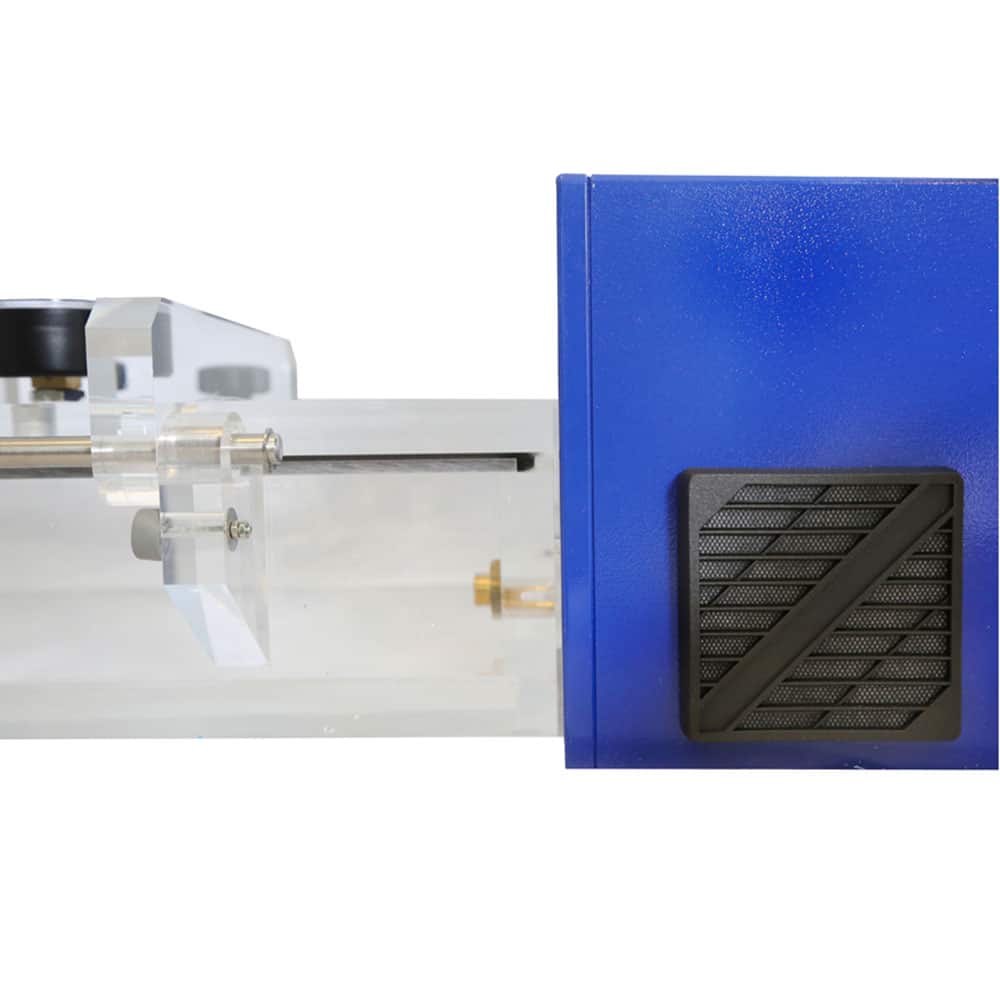

- Easy and quick maintenance due to the absence of electrical connection

Need full traceability and CFR 21 Part 11 compliance? Discover Agileak, our advanced leak testing solution.

Packaging leak tester CTE technical information

| Chamber | Transparent PMMA chamber on hinge |

| Range of measurements and accuracy | From -0.1 to -0.85 Bar as standard. Accuracy + / -2 % |

| Useful dimensions | Length (L) x Depth (D) x Height (H) It depends on the size of box. |

| Reading the depression | Needle pressure gauge 50 mbar resolution |

| Units | Bar, Psi |

| Air supply | – On compressed air 7 bar network connected to Rislan® 8mm pipe. (not included) |

| Depression adjustment | Regulator with filter |

| Depression time | Adjustable time device from 0 to 999 s |

| Principle of the test | Visual |

| Temperature | From 0 to 40°C |

| Standards | ASTM D4991, ASTM D5094, ASTM D4169, EN14401, DIN55528 |

Options

| Decrease in depression time (venturi more powerful) |

| Air drain valve for easy return ti PA |

| Safety gas springs |

| Adjustable time device from 0 to 99 999 seconds |

| Manovacuometer with needle with better resolution |

The packaging leak tester is delivered with:

A calibration certificate LNE / COFRAC