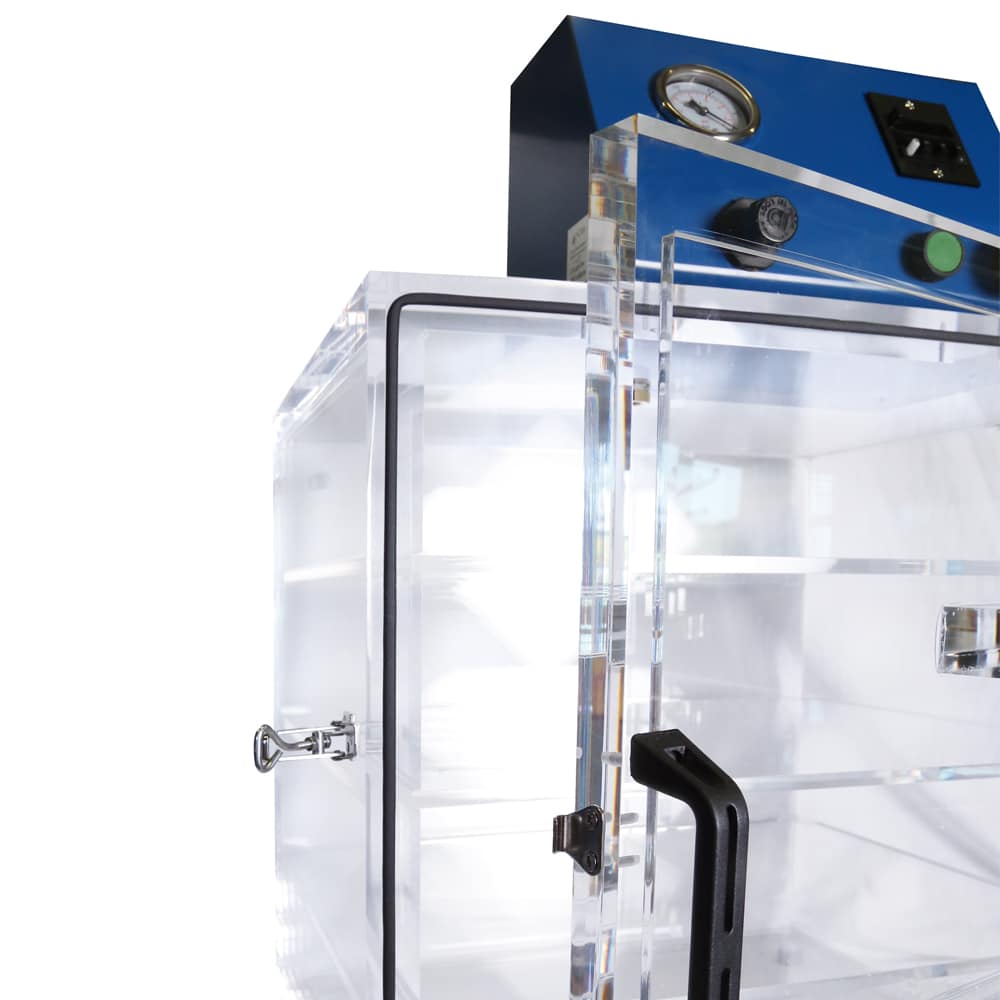

CTE-GM Leak test box

The big box

With a total visibilityand thanks to his plexiglass design, it is very quick and easy to see if there is a leak on the packaging.

It is most often used in edge industries of production line for its simplicity and fully pneumatic operation and for his big capacty to control big series. It is very useful in case of quality crisis or during an audit to control a whole lot.

Most often used for vials or bottles, it is also used to remove air bubbles and impurities in the enamel, emulsion, or those present before braizing or welding.

Description

Benefits

- Fully pneumatic

- Quick and simple test for large series

- Available trolley for a better mobility

- Layout with shelf for a large serie of samples

Options

| Air drain valve for easy return to PA. |

| Support trolley for a better mobility |

| Adjustable time device from 0 to 99 999 seconds |

| Needle vacuum gauge with a better resolution |

Included

A calibration certificate LNE/COFRAC

Information complémentaires

| Box | Transparent PMMA box with front door opening |

|---|---|

| Range of measurement and accuracy | From -0.1 to -0.85 Bar as standard. |

| Useful dimensions | Length (L) 500 mm x Depth (D) 450 mm x Height (H) 500 mm |

| Reading the depression | Needle pressure gauge 50 mbar resolution |

| Units | Bar, Psi |

| Power supply | – On compressed air network from 6 to 8 bars connected to Rislan® 8mm pipe (not included) |

| Weight | Weight: 60 kg |

| Thickness | 30 mm depending on the RDM study |

| Depression adjustment | Regulator with filter |

| Depression time | Adjustable time device from 0 to 999 s |

| Principle of the test | Visual |

| Temperature | From 0 to 40 °C |

| Standards | ASTM D4991, ASTM D5094, ASTM D4169, EN 14401, DIN55528 (Part 1, 2, 3, 4 , 5) |