In the cosmetic, pharmaceutical, and food packaging sectors, the tightness of packaging plays a fundamental role in the quality and safety of the final product. A bottle or tube may appear to be perfectly compliant during a visual inspection, yet have a micro leak that is invisible to the naked eye. This type of defect, which is often underestimated, can nevertheless lead to contamination, loss of product stability, or regulatory non-compliance. The detection of these micro leaks therefore relies on specific testing methods, which are much more reliable than human inspection alone.

Understanding what a micro leak in packaging is

A micro leak is a minor alteration in the seal of a package, usually located at a weld, crimp, cap, or sometimes directly in the plastic material. Its size is often below the threshold of visual detection, making it undetectable during a simple inspection with the naked eye. However, under the effect of pressure, vacuum, temperature, or transport, this micro-leak can develop and cause an actual leak of the product contained.

Why is visual inspection insufficient?

Visual inspection remains useful for detecting obvious defects, such as a clear crack, significant deformation, or a major manufacturing defect. However, it does not allow you to identify a micro-leak that does not manifest itself immediately. In many cases, the product only leaks after several days or even weeks, when the packaging is subjected to mechanical or thermal stress. It is precisely for this reason that manufacturers rely on instrumented leak testing methods to ensure the reliability of packaging before it is placed on the market.

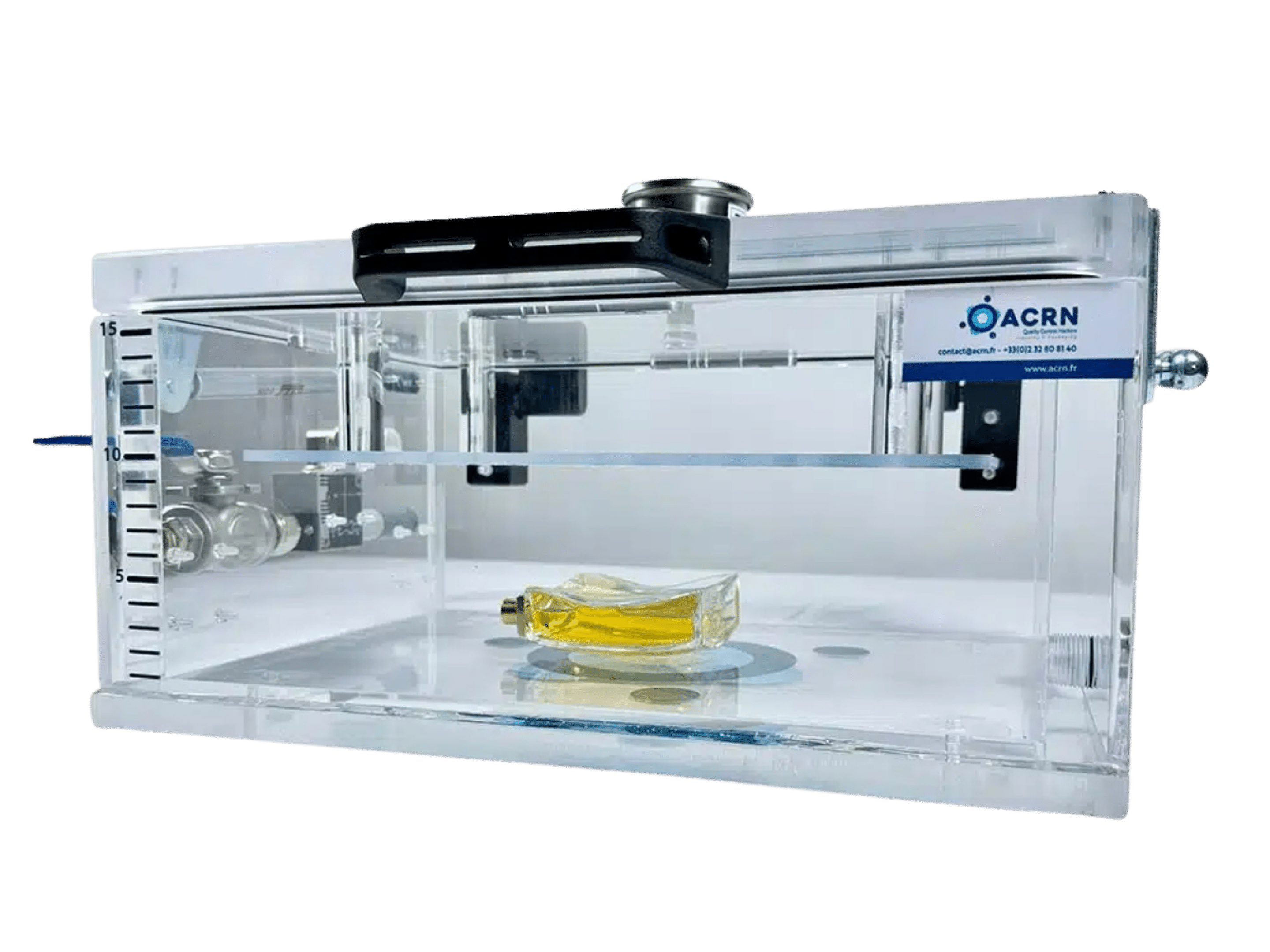

Immersion leak testing, an effective visual method

The immersion test, often referred to as the bubble test, involves pressurizing the packaging and then immersing it in a water bath. When a micro leak is present, fine air bubbles appear at the exact location of the defect. This method is particularly effective for detecting active leaks, even very small ones, on bottles, tubes, or jars. It is widely used in quality control because it allows immediate visualization of the leak. Depending on the industrial context, this test may be considered destructive, particularly when the product is already packaged.

Vacuum testing to reveal invisible defects

Vacuum testing is based on the opposite principle to pressurization. The packaging is placed in a chamber where a vacuum is created. In the event of a micro leak, air or the product contained may escape, making the defect detectable. This method is particularly suitable for rigid and semi-rigid packaging, such as vials or certain bottles. It offers excellent sensitivity and can detect defects that would remain invisible under normal conditions of use.

Pressure loss measurement for a quantitative approach

Some methods for detecting micro-leaks are based on measuring pressure variations over time. The packaging is pressurized, and then the pressure change is monitored precisely. An abnormal drop indicates the presence of a leak. This approach has the advantage of providing measurable and reproducible results, making it particularly useful in a quality validation or audit context. However, it requires precise configuration, as the sensitivity of the test depends on the volume of the packaging and the nature of the material.

Packaging affected in all sectors

Micro leaks do not affect any particular type of packaging. They can appear on plastic bottles, flexible or multilayer tubes, cosmetic jars, as well as on caps or closure systems. Even packaging that appears to be perfectly compliant may have an imperceptible leak that cannot be detected without appropriate testing. This is why these controls are now essential in many industrial sectors.

When to integrate a micro leak test into a quality process

Micro leak detection occurs at various stages of the production cycle. It can be carried out during the validation of a new packaging line, during quality control during manufacturing, or before a product is placed on the market. In certain fields, particularly pharmaceuticals, these tests are part of a strict regulatory process designed to ensure product safety and compliance.

How to choose the most suitable detection method

The choice of detection method depends on several factors, such as the type of packaging, the desired level of sensitivity, or production constraints. In practice, immersion tests and vacuum tests remain the gold standard for detecting micro-leaks invisible to the naked eye, as they offer an excellent compromise between reliability, simplicity, and efficiency.

Conclusion

Detecting a micro-leak invisible to the naked eye in a bottle or tube is essential to ensuring the quality, safety, and compliance of packaging. Visual inspection alone is not sufficient when dealing with such subtle defects. Only appropriate leak testing methods can identify these micro-leaks before they become a problem during storage, transport, or end use of the product. Implementing a reliable detection solution means securing your industrial process and preserving product quality all the way to the end consumer.