Introduction

In the world of packaging, the reliability of welds is a key factor. A fragile or poorly executed weld can have serious consequences: product leakage, loss of tightness, contamination, or even the recall of entire batches. To avoid these risks, manufacturers need accurate measuring tools capable of verifying the quality of seals. The Peeltest, also known as a peel test bench, is an essential solution as it allows the mechanical strength of welds to be checked and ensures that packaging complies with current standards.

What is a Peel tester?

Definition of Peel tester

The Peeltest is a measuring instrument that evaluates the force required to separate two bonded surfaces. It is mainly used to test the strength of flexible packaging such as plastic films, bags, blister packs, and medical pouches.

Operating principle

The sample to be tested is cut and then inserted into the Peeltest jaws. The machine applies controlled traction to both welded parts and records the force applied until breakage occurs. This makes it possible to determine whether the weld is uniform and sufficiently strong to meet safety requirements.

Difference from other test equipment

Unlike a tensile testing machine, which measures the overall strength of a material, the Peeltest focuses exclusively on the quality of welds. It is a tool specialized in evaluating sealants, not raw materials.

Why use a peel tester?

Ensuring the quality of welds

The Peeltest ensures precise control of the adhesion and regularity of welds. It highlights invisible defects, such as insufficient pressure, incorrect temperature settings, or the presence of impurities in the sealing area.

Compliance with standards and regulations

Many industries require standardized testing to validate packaging compliance. In the medical and pharmaceutical fields, for example, ISO 11607 defines the criteria for validating sterile packaging. The food and cosmetics industries are also subject to strict controls to ensure health safety and consumer satisfaction.

Risk and cost reduction

A packaging defect can have major financial and reputational consequences. Using the Peeltest helps limit product losses, avoid costly recalls, and protect the brand against litigation related to non-compliance.

The main applications of peel testing equipment

Agri-food sector

Packaging bags, trays, and films must be completely airtight to preserve food quality. The Peeltest validates the strength of welds and prevents any risk of leakage or contamination.

Pharmaceutical and medical industry

In this sector, safety is vital. The Peeltest is used to check the strength of welds on infusion bags, tablet blister packs, or sterile pouches. These tests ensure that the packaging remains sterile and tamper-proof until use.

Cosmetics and hygiene

Single-dose packaging, samples, and sealed sachets must be sturdy but easy for consumers to open. The Peeltest allows you to find the right balance between weld strength and ease of opening.

Various industrial applications

Beyond the food, medical, and cosmetics industries, Peeltest is used for technical or specific packaging in industry. Integrated directly into production lines, it provides fast and efficient quality control.

How does a peel test work?

Sample preparation

The operator cuts a strip containing the weld to be analyzed, usually in a standardized format. This step is essential for obtaining representative and comparable results.

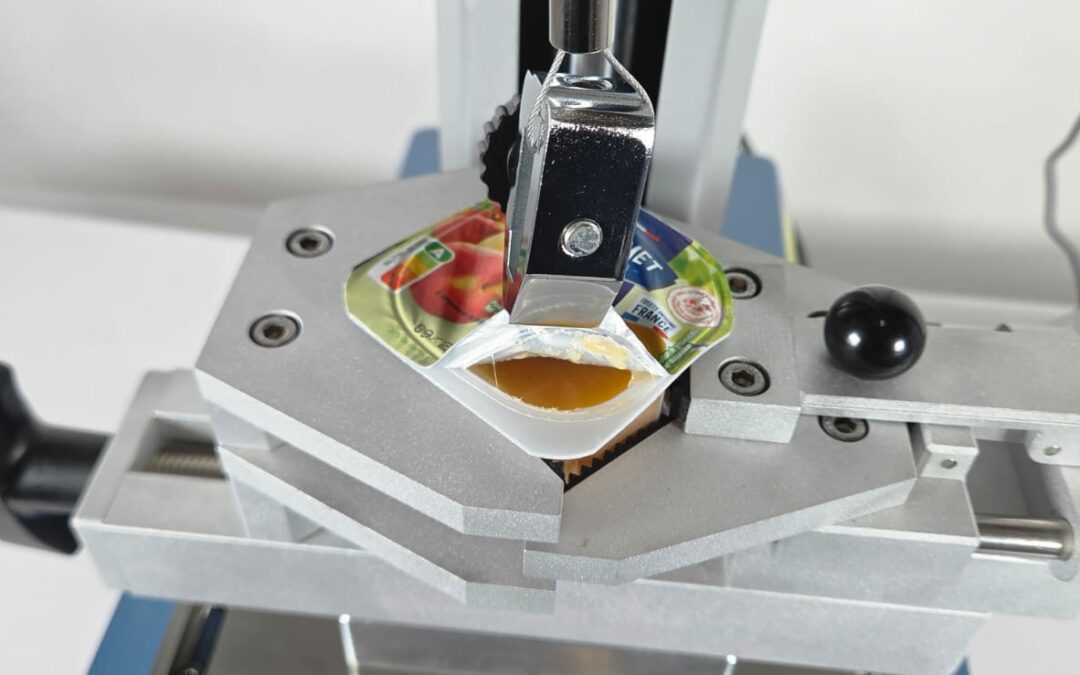

Installation in the machine

Both ends of the weld are placed in the Peeltest jaws. The hold must be firm and steady to avoid measurement errors.

Application of traction

The machine exerts a progressive force at a constant speed. This traction reproduces the mechanical stress that the packaging will undergo during use.

Analysis and results

The Peeltest records the force applied in the form of numerical values and graphical curves. These data reveal the maximum separation force, the homogeneity of the weld, and the type of failure observed (film rupture, delamination, weld tear).

Peel testing solutions offered by ACRN

Precision equipment

ACRN designs Peel testers capable of providing reproducible and reliable results, even in demanding environments. High-performance sensors guarantee accuracy in line with industrial and regulatory standards.

Simple and versatile use

Our machines are designed to be intuitive, both in the laboratory and on the production line. They can be adapted to different packaging formats: food pouches, medical bags, or cosmetic packaging.

Custom options

Each sector has its own constraints. ACRN offers customized configurations to meet specific needs, whether it be integrating a standard protocol, adjusting the test speed, or customizing the user interface.

Conclusion

The Peeltest is an essential tool for ensuring the quality and compliance of sealed packaging. It enables compliance with the most stringent standards, reduces the risk of non-compliance, and ensures the safety of consumers and patients. In a context where reliability and safety are essential criteria, its use is indispensable. ACRN supports manufacturers with high-performance, accurate Peeltests tailored to each sector.