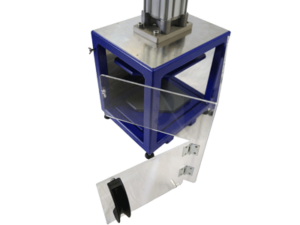

ATS-XD Modular Electro-Pneumatic Welding Tester

The modular electro-pneumatic model

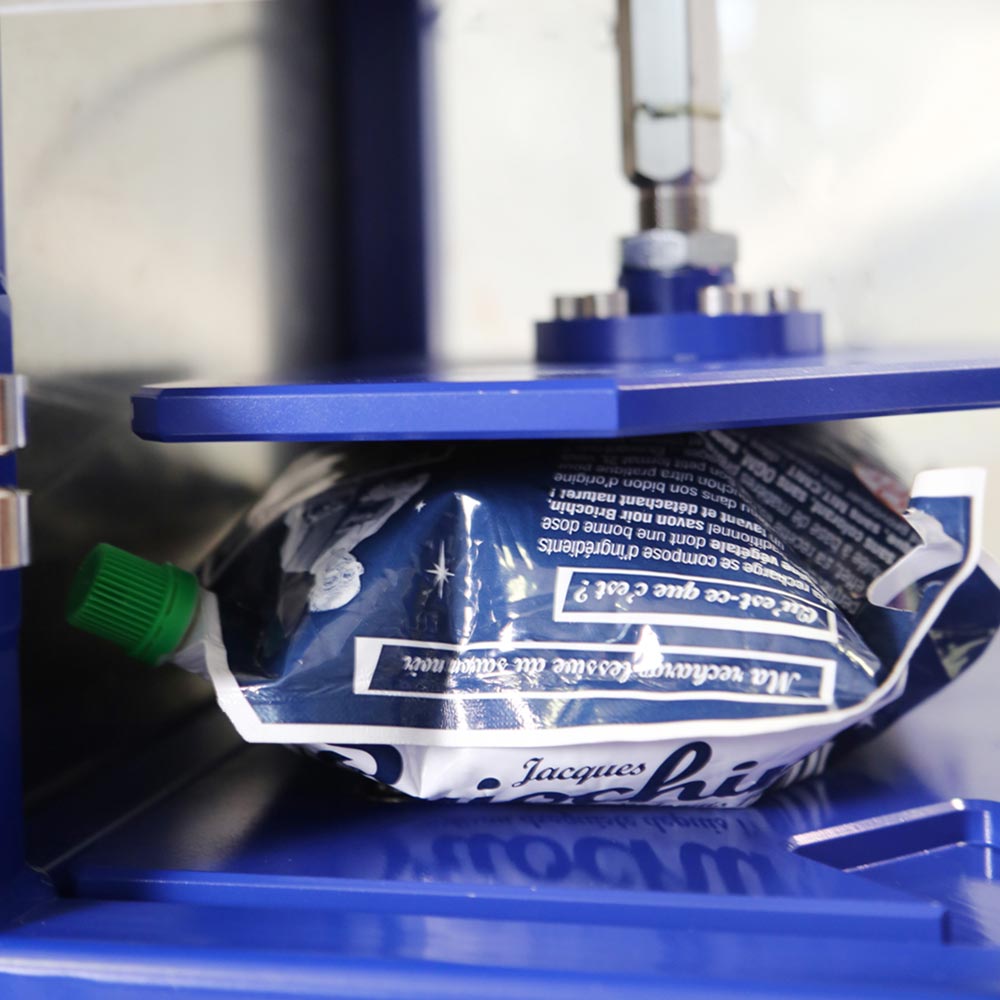

The electro-pneumatic ATS-XD is suitable for doypacks, pouches and tubes of all kinds.

For an utilisation on the production line or in the laboratory.

Why do you have to test your weld ? During the heatsealing process, defects in the weld can appear dur to the temperature of the electrodes and the presence of impurities. The implementation of a crush test allows to verify the integrity of the weld of your sample, and thus the absence of leakage or microleakage. This test is essential to validate the reliability of the weld.

This is a fast, simple and totally repeatable test deployed by many packaging manufacturers.

Description

Function

The ATS-XD weld tester is used to check the weld strength of plastic or metal packaging containing liquid or semi-viscous products such as: doypack, doypack refill, pouch, bag, tube.

Two tests

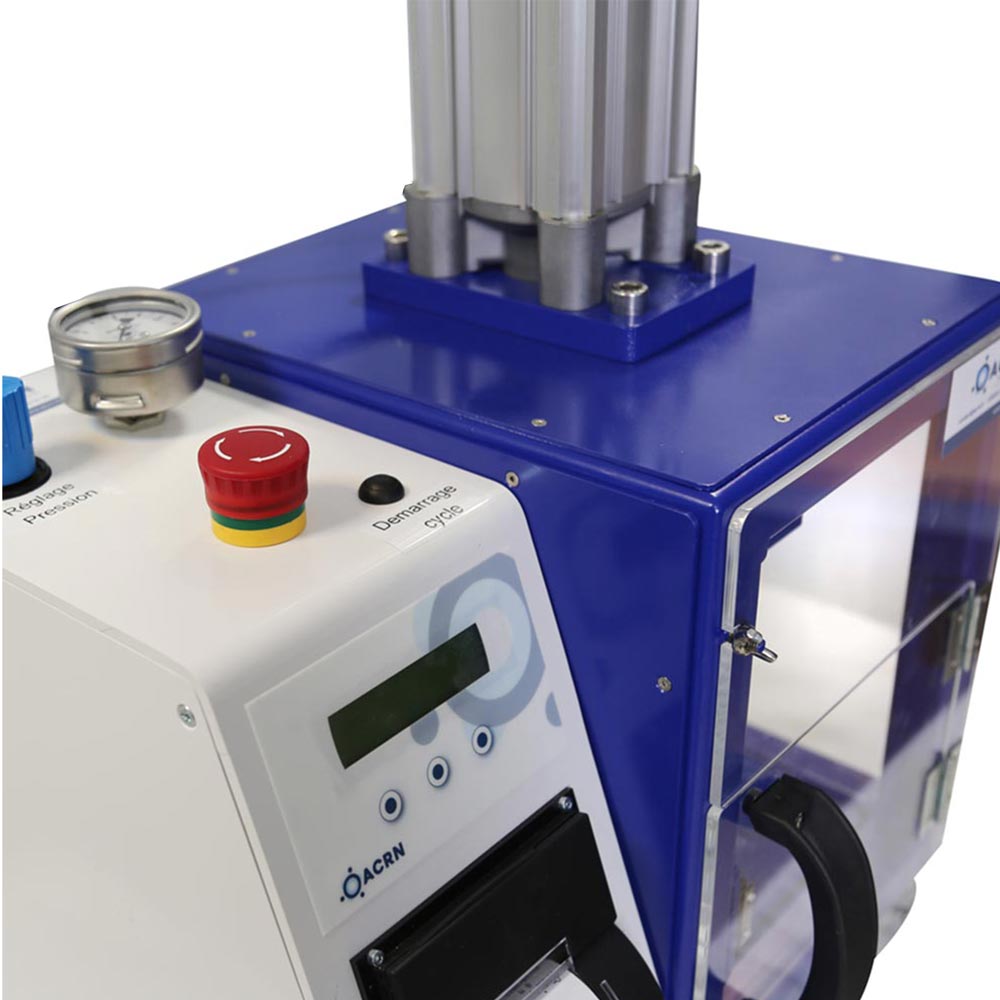

The advantage of this product is that it canperform two different tests thanks to its digital interface in which the user can vary the pressure force and test duration.

- Test with micro-leakthat grows with the pressure and causes a burst

- Burst test to determine the resistance of welds

Benefits

Adapted to production environments thanks to innovative and intuitive design:

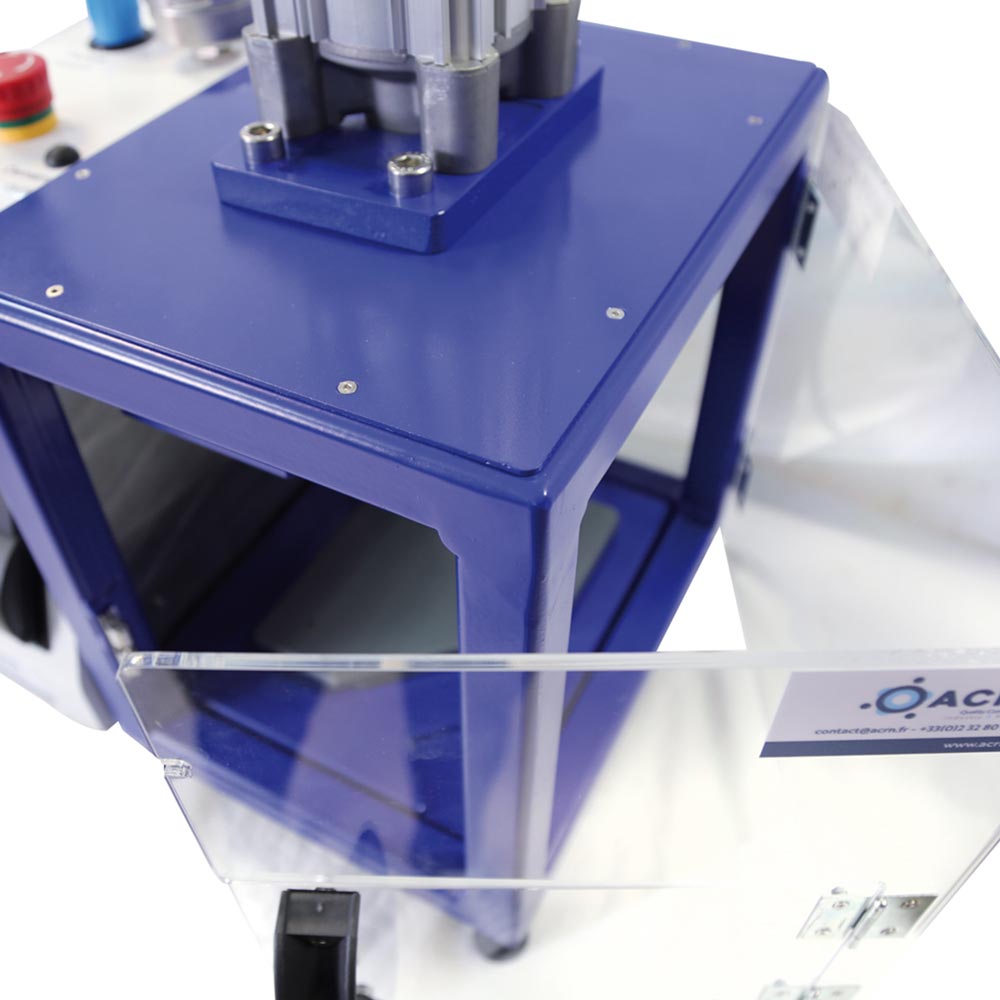

- Cleanability thanks to its multi-opening door

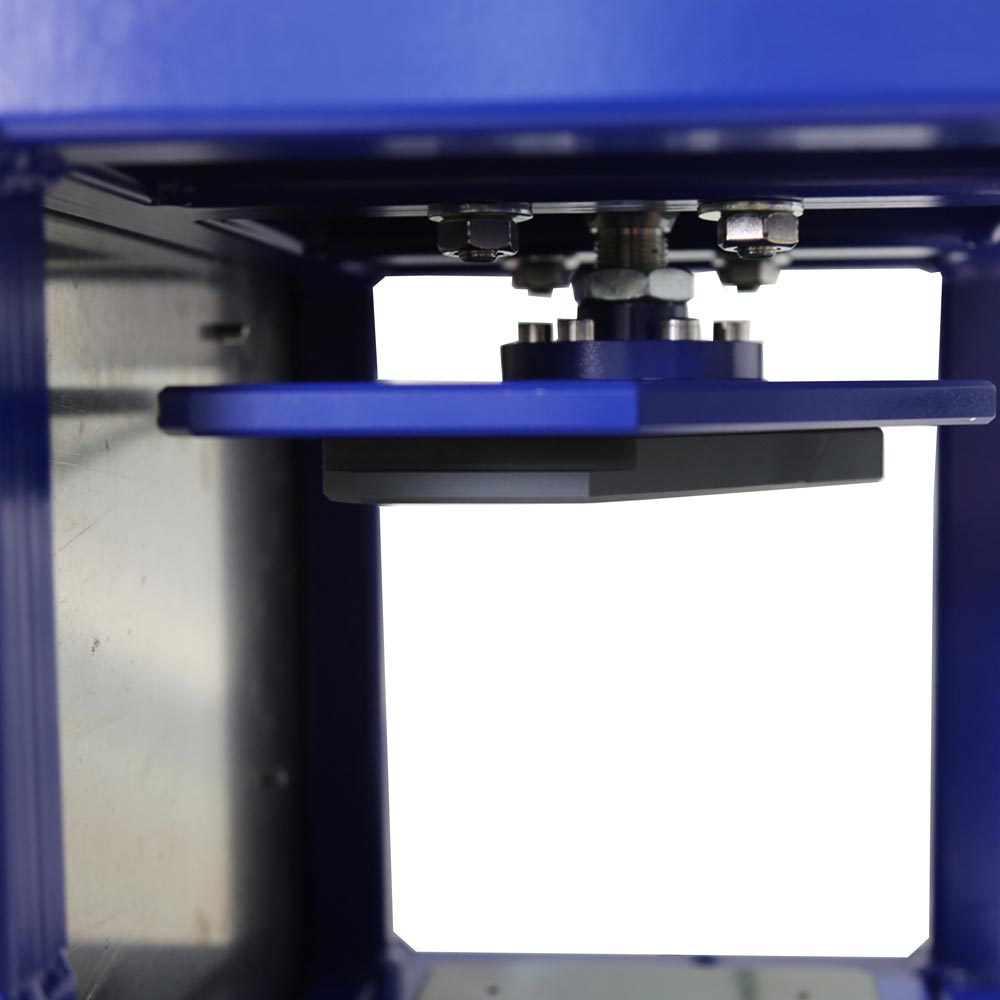

- Magnetic pressers quickly interchangeables according to the type of packaging

- Wide range of capacities from 10 kg to 3,300 kg in pressure force depending on the pneumatic cylinder

Easy to use digital interface with traceability of results via printer

Precise location of the leak

No maintenance

Specific housing on request for precise adjustment of the positioning of your samples ensuring very good repeatability of your measurements

Options

| Specific pressers |

| Specific support plate |

According specifications according to the support face

| ATS-XD 400 | ATS-XD 2200 | ATS-XD 3300 | |

| Force min | 20 kg | 400 kg | 400 kg |

| Force max | 400 kg | 2 200 kg | 3 300 kg |

| External dimensions | L 530 * D 400 * H 700 mm | L 400 * D 340 * H 580 mm | L 400 * D 340 * H 580 mm |

| Inside dimensions for sample | L 200 * D 270 mm | L 200 * D 270 mm | L 200 * D 270 mm |

| Weight | 25 kg | 65 kg | 65 kg |

Technical informations

| Crushing of doypacks | PVC doypacks crusher on rigid metal frame, unbreakable transparent polycarbonate door Painted mild steel support frame |

|---|---|

| Air supply | Compressed air from 0 to 10 bars |

| Power supply | 220 – 230 V / 50 – 60 Hertz |

| Pressure adjustment | Pressure regulator |

| Reading | Pressure gauge graduated from 0 to 10 bars |

| Timer | Adjustable from 2 to 999 secondes at + / – 1 seconde |

| Security | Emergency stop button / door switch |

| Power supply connection | Connection to the compressed air network by means of a Rislan tube with an external diameter of 8mm |

| Digital output | RS232 |