Torque measurement

Welcome to ACRN, where cutting-edge technology meets industry-leading precision. Our high-quality torquemeters are crafted to deliver unparalleled accuracy and reliability, essential for a diverse range of industries including cosmetics, pharmaceuticals, food processing, and viticulture. At ACRN, we understand that the backbone of efficient industrial operations lies in precise torque measurement, which ensures that machinery and production lines operate within their optimal parameters, thereby enhancing overall productivity and safety.

In the cosmetic and pharmaceutical industries, the accurate application of torque affects not only the safety and integrity of product packaging but also compliance with stringent regulatory standards. Our torquemeters facilitate precise tightening of caps and closures, preventing contamination and ensuring consumer safety. Similarly, in the food and beverage sector, including viticulture, effective torque measurement is crucial for preserving the quality and freshness of products, from bottling to packaging.

Explore our range of torquemeters to find out how they can enhance the precision and durability of your critical applications, contributing to a more reliable and efficient production process. Trust ACRN to elevate your operations with tools that push the boundaries of technological advancement and operational excellence.

-

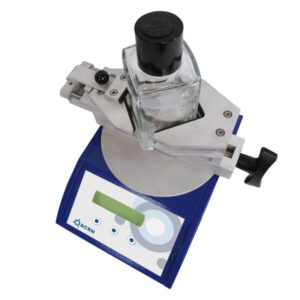

Electronic torquemeter (16)

-

Torque tester (4)

-

Static torque sensors and industrial screwdriver control (1)

-

Torque wrenches and screwdrivers (15)

-

Other torque controllers (1)

What is a torquemeter ?

A torquemeter is a high-precision measuring instrument used to measure the torque of a system. The term “torque” refers to the rotational force applied to an object. Torque is measured in units of Newton-meters (Nm) or pound-feet (lb-ft), and is often used to describe the rotational capacity of a motor or gear.

A torquemeter measures the torque of a system, which is an important physical quantity in many fields such as engineering, mechanics, car manufacturing, etc. A torquemeter can be analog or digital.

Torquemeters can be analog, but the vast majority of torquemeters are electronic.

What other names are used for torquemeter ?

This measuring system may also be called: Table torquemeter, torquemeter or bottle torquemeter.

In which sectors are they used?

Torque gauges are mainly used in the packaging industry.

During bottling, the tightening torque of the “cap-bottle” system must be adapted so that it does not fall below a minimum threshold (risk of leakage, external contamination) and exceed a maximum threshold (risk of very difficult opening or deterioration of the cap). The torquemeter can be used to measure the tightening/untightening force in the following applications:

Cosmetics: screw-pump perfume bottles (perfumes, creams, lotions, etc.)

Food industry: milk, soda and mineral water bottles, as well as anything that can be closed with a cap (groceries, bulk goods). Closures with safety collars (or tamper-evident rings) are a particularity of the sector taken into account by our torquemeters.

In the pharmaceutical industry: many medicines are packaged in bottles and closed with screw caps (capsules, syrups, etc.). The speciality of this sector is the CRC safety cap, which ACRN has experience of.

In the wine sector, wine merchants and suppliers of wine-making equipment use torque meters to measure the torque of wine bottles closed with screw caps. ACRN torquemeters are particularly well-suited to mobile bottling control.

In the chemical industry, they are used to test the closure of cans (e.g. oil, lubricant or phytosanitary product cans), electronic cigarette refills, etc.

Manufacturers of plastic/glass/wood packaging (bottles, corks, pumps, flasks): the plastics and glass industries also use ACRN torquemeters for quality control.

In industry, torque measurement is used in a wide range of applications:

– controlling the torque of torque wrenches and torque screwdrivers used for controlled tightening and screwing operations

– torque control (e.g.: lipstick or lip balm mechanisms, rotating opening mechanisms for automotive components (e.g.: windscreen wipers, storage drawers, armrests, etc.).

– test the torsion of components

What are the advantages of ACRN torquemeters?

In all these sectors, the needs and nature of controls are highly varied. Working with our industry experts, we will study all your problems.

We’ll study your product diversity and shapes, to propose clamping systems that are interchangeable and fast. We’ll select the right torque range for the right sensor, and the right precision. We can provide you with best practices for successful, repeatable torque testing, as well as the correct use of accessories to ensure high accuracy of results.

Our equipment is robust, designed to be upgradeable and repairable. We guarantee the longest service life on the market for our equipment.

Over the last few years, we have been involved in a number of projects involving the computer connection of torquemeters to support the digitization of in-plant quality control (traceability, Dataintegrity). Our equipment and our experts are ready to meet your needs.

How does a torquemeter work ?

The principle of a torquemeter is to measure the unscrewing torque of bottles, flasks and samples taken at random from the production line.

For the values to be respected, there are torque measurement charts that depend on the cap and diameter. We can provide you with the usual torque measurement specifications to help you acquire the right equipment.

Is the torque test easy to deploy?

This test is widely used in the food, cosmetics and pharmaceutical industries, as well as by screw and spirits manufacturers/packagers. It’s easy for operators to use and inexpensive to deploy.

What else does a torquemeter do ?

These torque testers are also used to test torque wrenches and other types of tooling. Please contact us if you’d like to set up a torque wrench test with a standard torquemeter, and we’ll be happy to set up a typical setting taking into account your measurement range and other parameters.